Technical Information Proportional Valve Group PVG 16 powersolutions.danfoss.com http://powersolutions.danfoss.com Revision history Table of revisions Date Changed Rev February 2017 Major update. 0401 March 2016 Minor update in PVHC technical characteristics 0303 March 2016 Updated to Engineering Tomorrow design. 0302 February 2016 Drawing was updated in topic: How to select the correct spool 0301 September 2015 PVG 16 Step II 0200 March 2015 PVH, PVMD changed under Modules BF February 2015 Seal kit added for PVB + PVM BE December 2014 PVHC section updated BD August 2014 PVEO pin descriptions…

File type: application/pdf

Referenced at:

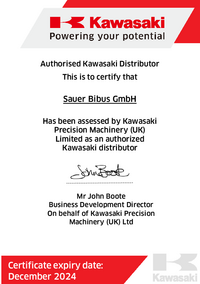

SAUER BIBUS ICVD®Integrated Continuously Variable Drive SAB-SD-001-e-12.08 1 ICVD® Integrated Continuously Variable Drive 1 Dokumentation ICVD® ID 50.20.0810 SAUER BIBUS GmbH Lise-Meitner-Ring 13 89231 Neu-Ulm www.sauerbibus.de ID 50.20.0830 ID 50.20.0850 ID 50.20.0820 ID 50.20.0840 ID 50.20.0860 SAUER BIBUS ICVD®Integrated Continuously Variable Drive SAB-SD-001-e-12.08 2 Inhaltsverzeichnis / Table of contents / Table des matières 1. Dokumentation ICVD Documentation ICVD 1.1 ICVD-kpl. ICVD-cpl 1.1.1 Gesamtansicht 5 - 16 Total view Vue d’ ensemble 1.1.3 Explosionsansicht 17 - 20 Explosion…

File type: application/pdf

Referenced at:

SAUER BIBUS ICVD®Integrated Continuously Variable Drive SAB-SD-006-e-12.08 1 ICVD® Integrated Continuously Variable Drive 1 Dokumentation ICVD® ID 50.20.1070 SAUER BIBUS GmbH Lise-Meitner-Ring 13 89231 Neu-Ulm www.sauerbibus.de ID 50.20.1080 SAUER BIBUS ICVD®Integrated Continuously Variable Drive SAB-SD-006-e-12.08 2 Inhaltsverzeichnis / Table of contents / Table des matières 1. Dokumentation ICVD Documentation ICVD 1.1 ICVD-kpl. ICVD-cpl 1.1.1 Gesamtansicht 5 - 7 Total view Vue d’ ensemble 1.1.3 Explosionsansicht 8 Explosion opinion Avis d’ explosion 1.1.4 Stückliste 9 - 11 Parts list Liste…

File type: application/pdf

Referenced at:

File type: application/pdf

Referenced at:

Das einzige komplette Angebot an Hydraulikverstärker-Lösungen MINIMUM SIZE – MAXIMUM POWER Geben Sie für nahezu jedes Fluid-Medium einfach Ihren Bedarf für einen Ausgangsdruck bis 5000 bar und einen Eingang bis 70 l/min an. So können Sie der folgenden Tabelle ganz leicht den optimalen Hydraulikverstärker entnehmen. Unsere breite Produktpalette deckt Ihren Bedarf B-DE-F1-Prospekt der Produktpalette-02 2 Aus- gangsdruc k bar Mittlerer Ausgang (l/min) Eingangs -druck (bar) Mittlerer Eingang (l/min) Anschluss Gewicht (kg) Verstär- kung Modell: Stahl Modell: Edelstahl Hinweise Modelle 24 - 800 0.3…

File type: application/pdf

Referenced at:

RT-310 Service and Repair Manual BLN-0078 January 2013 RT-310TM i TABLE OF CONTENTS SECTION PAGE Tear down and reassembly.....................10-12 How to Use This Manual...................10 General Instructions..........................10 Tools..................................................11 Torques...............................................11 Removal............................................12 RT-310TM Tear Down and Assembly........13-25 Fan and Pulley Assembly..................13 Control Arm Assembly.......................14 Side Housing.....................................15…

File type: application/pdf

Referenced at:

RT-310 Service and Repair Manual BLN-0078 January 2013 RT-310TM i TABLE OF CONTENTS SECTION PAGE Tear down and reassembly.....................10-12 How to Use This Manual...................10 General Instructions..........................10 Tools..................................................11 Torques...............................................11 Removal............................................12 RT-310TM Tear Down and Assembly........13-25 Fan and Pulley Assembly..................13 Control Arm Assembly.......................14 Side Housing.....................................15…

File type: application/pdf

Referenced at:

DESIGNED FOR THE TOUGHEST JOB Engineered for both power & durability, providing unmatched performance for the long haul The RT-310’s infinitely variable output speed provides superior control to power through the toughest chores Maintenance-free design for longer life RT -3 10 ™ Specifications subject to change without notice EFFICIENT & RELIABLE RT310-09/2016-V1 FOR MORE INFORMATION VISIT: WWW.HYDRO-GEAR.COM DESIGNED & ASSEMBLED IN THE USA SPECIFICATIONS Overall Transmission Reduction 3.4:1 Pump Displacement 0.18 in3/rev [3 cc/rev] Motor Displacement 0.62 in3/rev [10.2 cc/rev] Input Speeds…

File type: application/pdf

Referenced at:

DESIGNED FOR THE TOUGHEST JOB Engineered for both power & durability, providing unmatched performance for the long haul The RT-310’s infinitely variable output speed provides superior control to power through the toughest chores Maintenance-free design for longer life RT -3 10 ™ Specifications subject to change without notice EFFICIENT & RELIABLE RT310-09/2016-V1 FOR MORE INFORMATION VISIT: WWW.HYDRO-GEAR.COM DESIGNED & ASSEMBLED IN THE USA SPECIFICATIONS Overall Transmission Reduction 3.4:1 Pump Displacement 0.18 in3/rev [3 cc/rev] Motor Displacement 0.62 in3/rev [10.2 cc/rev] Input Speeds…

File type: application/pdf

Referenced at:

PIM00194 4 Hybrid Hydraulic System Super Unit for Molding Machine SUT00S5021/SUT00S8018 SUT00S13018/SUT00S13021 SUT00S20018 Operation Manual 【ORIGINAL INSTRUCTIONS】 Oil Hydraulics Division PIM00194 4 Introduction Thank you for selecting the SUPER UNIT of DAIKIN Hydraulic System. This operation manual describes how to operate this SUPER UNIT, and maintenance/inspection, troubleshooting procedure and specifications of this system. Before using this product, be sure to read through this manual carefully to ensure proper use of the system. General Precausions ● Improper operation or handling of…

File type: application/pdf

Referenced at: